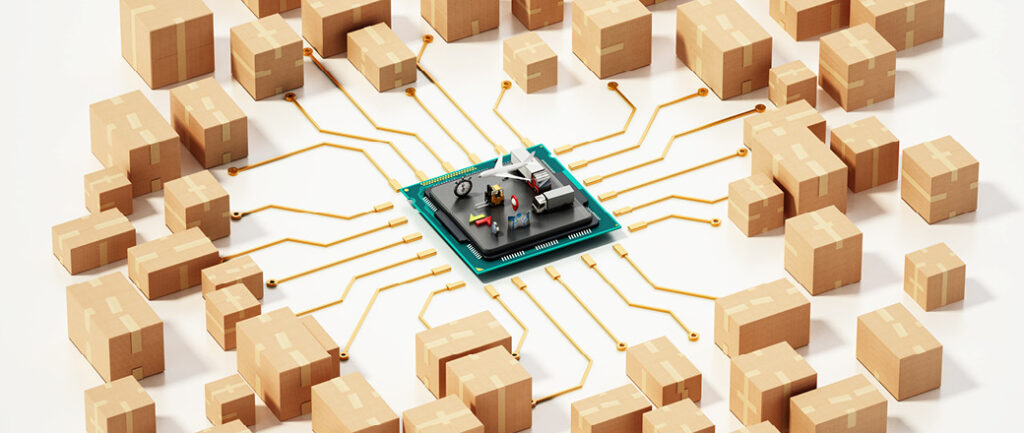

The value of automation in logistics is rapidly becoming synonymous with supply chain efficiency. To help you create more value within your supply chain, let’s explore how the evolution of transportation processes supports new avenues to deploy automation.

In this blog, we’ll discuss common misconceptions about autonomous logistics and opportunities a path forward with automation in logistics can improve your transportation management. Keep reading for tips to help you implement more automated activities across your processes.

Misconceptions About Automated Technologies in Logistics

Automation in logistics does possess somewhat of a negative connotation. When people think “autonomous logistics” they might first think about the Hollywood-made an entire archetype out of the idea of an upcoming “Robot Apocalypse.” At the same time, today’s employees worry about what automation in logistics could mean for their future in the workplace.

Likewise, the evolution of automation is not as exciting as its big-screen identity suggests. Logistics automation began with printing presses capable of copying documents, and it continued as digital technologies made it easier to share information in other ways. Remember the fax machine? Then email. Now, EDI makes sharing information seamless, and it is possible to share information in real time.

For today’s supply chain, automation of transportation management execution based on a series of predefined rulesets can trigger a series of subsequent events.

Automation plays a critical role in your ability to manage:

Automation in logistics is more mundane than robots taking over the world, but it can have a big impact in real-life.

Process automation in your logistics operations supports faster, smoother data sharing and freight shipment execution.

Opportunities to Deploy Automation in Logistics

Automation technology can be applied across nearly any redundant process. What is more repetitive or redundant than some of the supply chain activities?

Opportunities to deploy automation can range from end-to-end across your transportation management: order processing, tendering, dispatching, settlement, auditing, report distribution – even event notification of exceptions.

According to Supply Chain Digital, technology applications include multi-shuttle systems for put-away and picking, analytics tools, optical recognition, 3D printing, innovative storage, and virtually any management system.

Even with all the innovations expanding automation within the transportation management system (TMS), organizations continue to rely on manual supply chain activities.

Tips to Apply Automation in Your Logistics Activities

- Start small with retrofits and self-reporting devices.

- Avoid building whole automation systems in-house.

- Connect your legacy systems to new platforms via API or EDI.

- Invest in a TMS that offers scalability via the cloud.

- Consult with one of our expert partners for additional help.

Calculate your potential Saving While Using an enterprise TMS

Reap Rewards From Automation in Logistics With the Right Partner

Automation takes time. Failure to consider all other implications across your other software, services, or systems could disrupt your entire network. That’s why more organizations turn to true experts like MercuryGate and our reseller partners. We can help you understand what to automate and where and when to take those steps.

Download our ebook for a deeper look at how you can maximize your TMS efficiency with automation.