Inflation and rising consumer demand pushing freight transportation costs higher in a tight market. In that environment, freight pooling capacity is appealing.

However, at other times, it is an effective strategy to maximize transportation capacity and ultimately limit empty vehicle miles.

How Freight Pooling Works

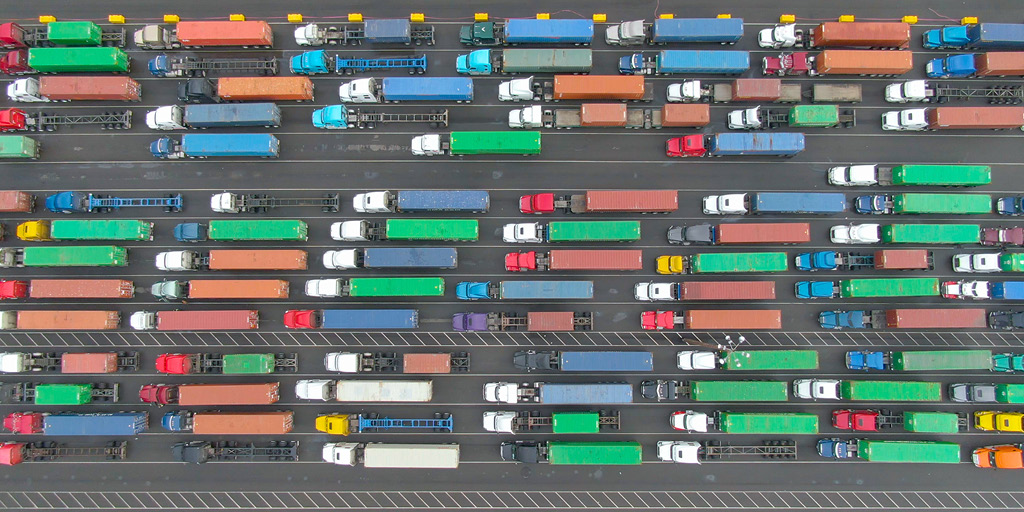

Freight pooling is when a carrier consolidates multiple less-than-truckload (LTL) shipments to transport them together to a localized pool point.

At the pool distribution point, freight is sorted according to its final destination and sent on its way for local final-mile delivery. These shared shipments can be multiple orders from the same shipper or distributor. Or they may be single large orders from multiple companies that are near in proximity to each other.

For example, a shovel distributor is trying to get a shipment to the Denver metro area ahead of the next snowstorm. Instead of hiring four trucks to take four LTL orders to separate areas in Denver, the shipper consolidates all four orders into one truck with freight pooling capacity. That truck then moves to a central location in Denver. At that point, the original truck offloads onto four separate final-mile carriers to get the shovels to their destinations.

6 Ways Freight Pooling Saves Money

It takes time to incorporate and become familiar with any new change in business operations. New methods need a proven ROI, even when the investment is nothing more than time. Shippers and distributors can see a savings ROI with freight pooling in multiple ways, including:

1. Less expensive TL contracts.

By sharing freight pooling capacity costs with another order, the individual order’s transportation costs can go down significantly compared to an LTL shipment.

2. Fewer trucks utilized.

Instead of paying for multiple LTL routes, consolidation means only one truck invoice to pay.

3. Reduced fuel costs.

Whether a shipper operates a fleet or outsources to a carrier, fewer trucks means reduced fuel expenses.

4. Minimized overhead expenses.

There is less need for a distribution center to dock for the hub-and-spoke model when using fewer LTL trucks.

5. Reduced risk of damaged product.

Because pooling requires fewer loads and unloads than LTL shipments, less handling can result in fewer damaged or lost products.

6. Split costs with another company.

By partnering with other stakeholders, shippers and forwarders can split the costs of traveling to a similar destination.

Strategies for Maximizing the Value of Freight Pooling

By pooling, shippers can improve customer service in logistics with the addition of a check-in point to track a timely delivery. Despite the addition of a check-in point, freight pooling still minimizes the overall time in transport and amount of times a product is handled compared to LTL.

The improved transit time, supply chain visibility, and minimized overhead costs are all huge benefits that promote customer retention.

Another way you can answer, “What is freight pooling?” “It’s a part of optimizing our company’s transportation sustainability.”

By using fewer trucks, companies decrease their carbon footprint and limit the wear and tear on equipment and vehicles. This efficient shipping strategy helps shippers and forwarders work together to reduce resource consumption.

Calculate your potential Saving While Using an enterprise TMS

Deploy Freight Pooling

See more strategies to optimize your freight management – without generating additional cost.